Heat exchangers for slurry and sludge

Optimal heat exchangers for slurry and sludge

Get a free review of your heat balance

Contact us today to get a free review and feedback on your heat balance

Can exchange slurry directly against slurry

Very few heat exchangers on the market can exchange slurry directly against slurry without a water circuit in between. This can be done in the Higashi exchanger without clogging and without sedimentation of sand. This results in much more efficient heat exchange as the temperature loss between the hot stream and the cold stream is much less overall. Simply put, much more energy is recovered.

Very low pressure drop

The heat exchanger has large channels that are dimensioned according to the substrate type and viscosity, and the exchanger can handle very low flow rates. Overall, a very low pressure drop is achieved across the heat exchanger on both sides. This results in low power consumption of the pumps.

Easy cleaning

If it turns out to be necessary to clean the heat exchanger at all, this has been taken into account. Openings at the ends make it easy to flush and clean the heat exchanger. There are no expensive special seals. It is also easy to connect a CIP system so that cleaning is carried out automatically with the addition of acid to the heat exchanger.

Efficient heat transfer

With viscous media such as slurry and sludge, laminar flow and poor heat transfer are easily achieved. This is prevented in the heat exchanger here, as there are continuously mounted turners inside the exchanger that ensure the substrate is continuously turned. This is done without adding any special pressure drop and without creating the possibility of fiber clogging.

Modularly built

The heat exchanger is built in regular modules that are easy to incorporate into a process building. They do not require much space in width, but of course, there must be room at the ends so that it is possible to access with flushing equipment if it becomes necessary to clean the exchanger.

Simple insulation

Depending on the operating temperature, it may be desirable to insulate the heat exchanger. This is very simply done as the flat sides of the heat exchanger make it easy to mount insulation of many different kinds. If there are several exchangers next to each other, it is also possible to make a common insulation box around the exchangers.

Why exchange heat slurry against slurry directly?

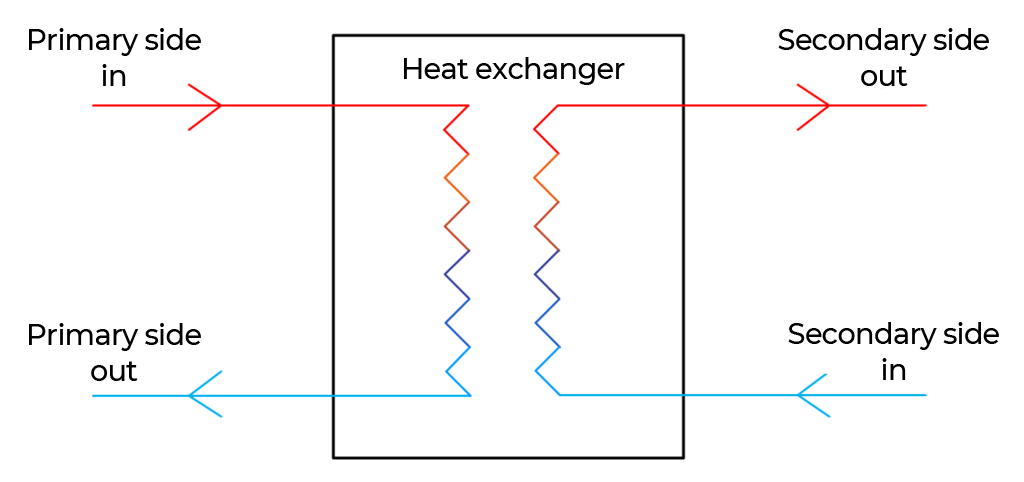

The most effective way to recover heat is by exchanging heat directly between the two streams that need to be cooled and heated.

Heat exchange with water circuit

Most solutions on the market require two heat exchangers with a water circuit in between. In the first exchanger, the heat from the slurry is transferred to the water circuit, in the second exchanger the water must then give off the heat to the cold slurry. Every time heat is exchanged, temperature is lost and with a water circuit in between, there is a temperature loss twice. It is not very efficient!

Direct heat exchange

If you exchange slurry or sludge directly against each other, however, you have only one heat transfer and one temperature loss. The heat transfer thus becomes much more efficient and much more energy can be transferred. In addition, you will save the electricity for the pump on the water circuit and a lot of space.

Get a price on a heat exchanger solution

We would very much like to calculate a price for an efficient heat exchanger solution for you.

Call or write to us for more information or fill out the form below if you already have some of the data needed to make a calculation.

Fill in the fields to get a calculation made

We can size and calculate a price for a heat exchanger for you if you fill out the form here.

The more information and the more accurately it is filled out, the better.

If you have questions about filling it out, call us at: +45 31 14 44 84